Emballage à base de papier

ACTEGA est un leader international de l'emballage flexible en proposant des encres, des revêtements et des adhésifs sur mesure.

EN SAVOIR PLUSLes feuilles d'aluminium offrent les propriétés de barrière optimales pour protéger le chocolat de la lumière et de l'humidité et pour garantir son goût indubitable, son odeur caractéristique et son aspect fin et brillant.

Une fois ces fonctions de protection assurées, l'emballage a une autre tâche extrêmement importante. Il doit convaincre par son aspect de haute qualité, prendre en compte les conceptions des propriétaires de marque et assurer l'attention sur le point de vente.

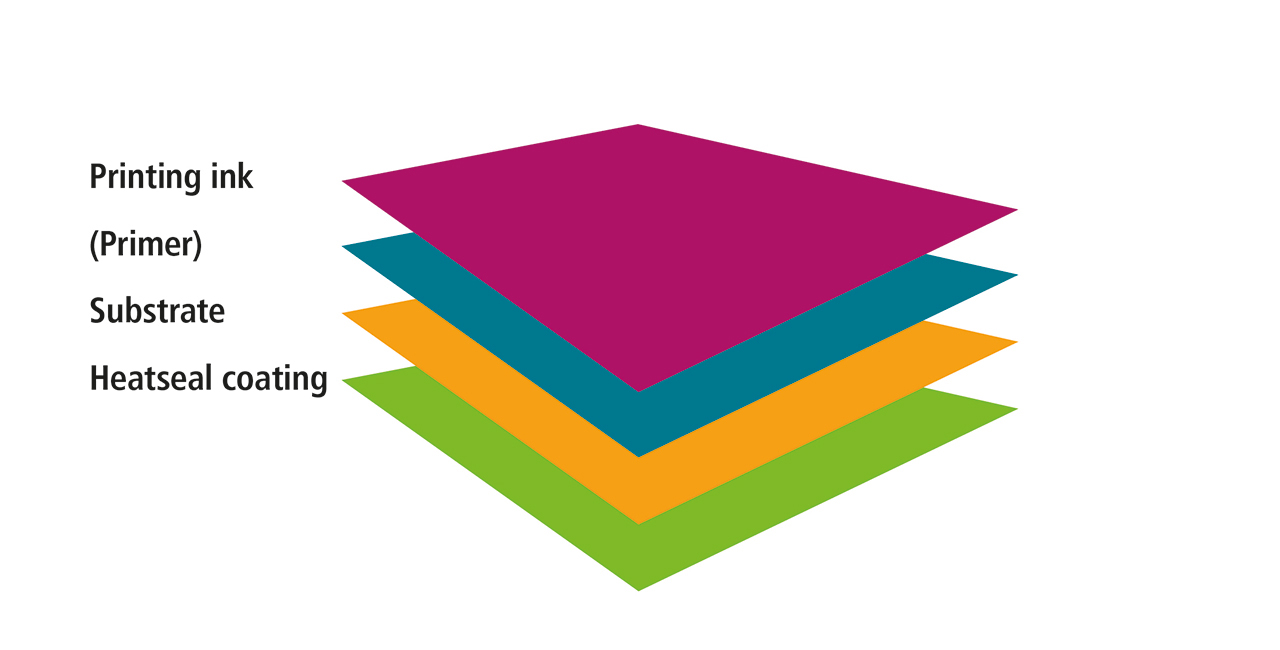

Le sceau de protection ACTEcoat® et les revêtements thermoscellants ACTEseal® d'ACTEGA garantissent des finitions attrayantes et une stabilité pendant le transport et le stockage. De plus, ils sont entièrement conformes à la réglementation alimentaire.

Do you have any questions? Contact us and we will be happy to advise you on your individual requirements.

CONTACTReliable protection of consumer health is our top priority. That's why we conscientiously test the safety of the raw materials we use and, as a matter of principle, only use materials that have been proven to comply with food regulations (including FDA and EU regulations). In order to meet not only current but also future market requirements, we are continuously developing our products.

The increasing demand for environmentally friendly and high-performance coatings is leading us to continuously expand and improve our product portfolio. In the area of protective and heatseal coatings, we offer both solvent-based and water-based systems. Under the aspect of sustainability, water-based coatings offer a number of advantages:

• Significantly less VOC than solvent-based systems

• No hazardous material storage required

• Reduced requirements for transport, occupational safety and fire protection

Answering the question which of the two systems is the more sustainable requires a differentiated case-by-case approach that considers various factors along the entire value chain. We therefore advise our customers to comprehensively and individually evaluate the appropriate product solutions for their specific needs.

Our product recommendations

Our product recommendations

Here you can also find out how you can use our effect coatings to impressively set the scene for your chocolate packaging.

DISCOVER