Flexible Packaging

ACTEGA is an international leader in flexible packaging by offering tailored inks, coatings and adhesives.

LEARN MORE

ACTEGA is an international leader in flexible packaging by offering tailored inks, coatings and adhesives.

LEARN MORE

Our focus on innovation is at the heart of our DNA, so we invest heavily in the development of new technologies.

DISCOVER MORE

Our goal is becoming climate-neutral by 2025. Discover more about our commitment to environmental protection.

DISCOVER MORE

Discover our calendar with great images and powerful finishing effects.

MoreYou have already subscribed to our newsletter.

You successfully unsubscribed from our newsletter

Continue ShoppingFoam is the result of air distribution in the coating. Here, gaseous bubbles emerge in the coating or on the coating‘s surface. If foam occurs in the coating container or coating pan, processing problems may be the consequence. This is followed by transfer disturbances or air inclusions in the dried coating layer.

The coated printed product looses gloss and/or scuff resistance. If foam appears in the chambered doctor blade or roller system, a (partial) drying of the coating is possible. Depending on the level of contamination, this may even lead to malfunctions of the printing press. The most usual reason for foaming is the fast pumping of the coating in the container (circulation of coating suction and return flow) and in the printing press.

If coating suction and return flow are positioned incorrectly, air can be taken into the coating. Strong foaming is the result. Therefore, install coating suction and return flow deeply below the coating‘s surface on the wall of the container.

If foaming continues to increase, return flow should be positioned above the coating‘s surface on the wall of the container so that the surface of the returning coating is as large as possible. This supports faster foam degradation.

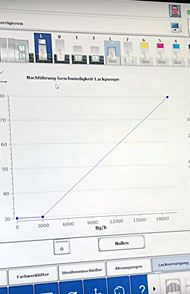

If your coating pump is running too fast, foam (mostly macro foam) may easily be formed. Choose the speed of your coating pump just as high as it is necessary for the coating unit to be filled and emptied properly.

New high-speed printing presses that mainly print large formats work often with a low volume chambered doctor blade system. In this case micro foam can be reduced by an increased pumping capacity and thus also and increased flow rate.

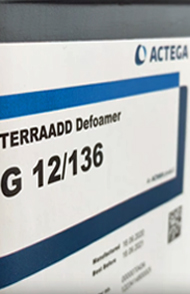

Defoamers eliminate and prevent foaming. If you add defoamer to your coating, pay attention to the correct dose. Otherwise it may come to an incompatibility between defoamer and coating. The consequence: altered coating characteristics and/or surface disturbances in the dried coating layer.

If you add defoamer to your coating, always ensure that the defoamer is thoroughly incorporated into the coating. If defoamer is added at the printing press, sufficient mechanical stirring is absolutely necessary so that the defoamer achieves its desired results.

Many coatings contain raw materials with a foam-building structure. These raw materials determine the foaming behaviour of a coating. Often, they are necessary for the functionality of the coating. A replacement is hardly possible. Please contact your technical representative or use the contact form below.

Fast running membrane or rotary pumps can positively influence the occurrence of foam. A peristaltic pump operates in a gentler way. However, increasing the flow rate to reduce micro foam is not possible when working with peristaltic pumps as they do not produce a sufficiently high flow rate.

Still have open questions? Contact us and we will support you with the application.

CONTACT USThe Troubleshooting Series is your source of content with smart tips that helps you to make the most of all ACTEGA products in your processes. In addition to state-of-the-art chemical specialties for the packaging industries, we are your knowledge partner by offering you our technical expertise and useful information.

Discover all of our content