Flexible Packaging

ACTEGA is an international leader in flexible packaging by offering tailored inks, coatings and adhesives.

LEARN MORE

ACTEGA is an international leader in flexible packaging by offering tailored inks, coatings and adhesives.

LEARN MORE

Our focus on innovation is at the heart of our DNA, so we invest heavily in the development of new technologies.

DISCOVER MORE

Our goal is becoming climate-neutral by 2025. Discover more about our commitment to environmental protection.

DISCOVER MORE

Discover our calendar with great images and powerful finishing effects.

MoreYou have already subscribed to our newsletter.

You successfully unsubscribed from our newsletter

Continue ShoppingChocolate is one of the most demanding foods when it comes to packaging. The packaging must not only protect the chocolate from external influences such as light or moisture, but also preserve its distinctive taste while being as light as possible, but also stable.

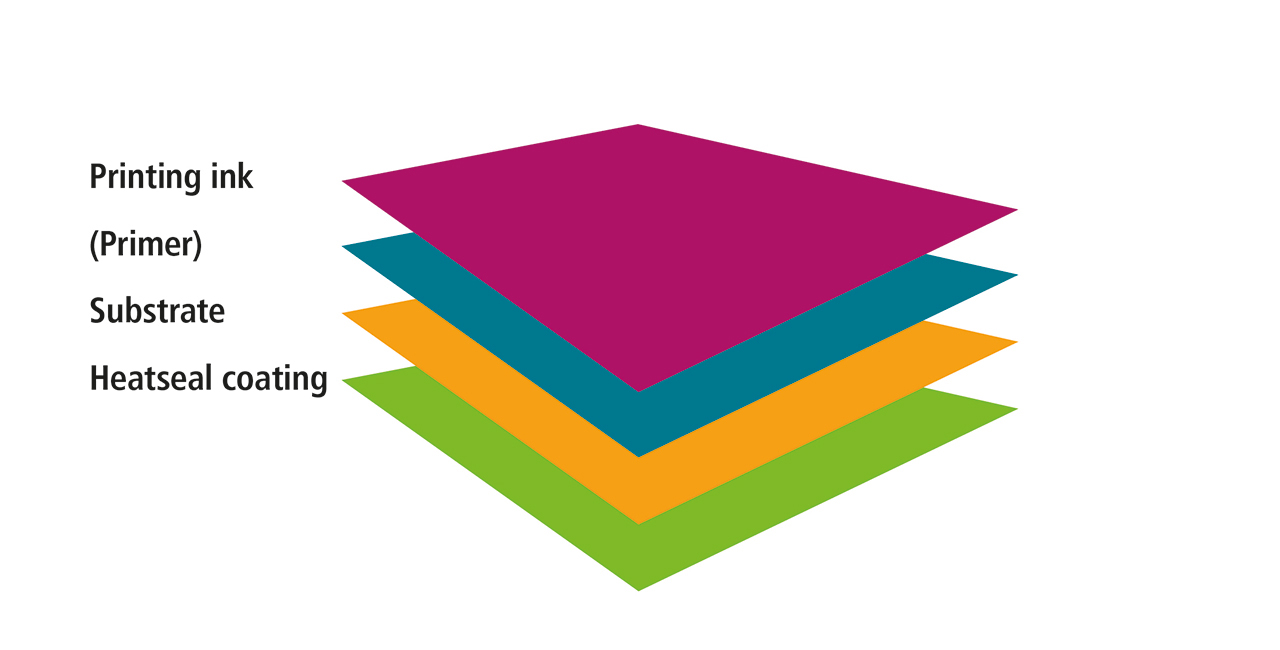

Our product portfolio includes both protective coatings and heatseal coatings for all common substrates (aluminum, plastic, paper), which provide optimum protection for the contents and are compliant with all standard food regulations.

Do you have any questions? Contact us and we will be happy to advise you on your individual requirements.

CONTACTReliable protection of consumer health is our top priority. That's why we conscientiously test the safety of the raw materials we use and, as a matter of principle, only use materials that have been proven to comply with food regulations (including FDA and EU regulations). In order to meet not only current but also future market requirements, we are continuously developing our products.

The increasing demand for environmentally friendly and high-performance coatings is leading us to continuously expand and improve our product portfolio. In the area of protective and heatseal coatings, we offer both solvent-based and water-based systems. Under the aspect of sustainability, water-based coatings offer a number of advantages:

• Significantly less VOC than solvent-based systems

• No hazardous material storage required

• Reduced requirements for transport, occupational safety and fire protection

Answering the question which of the two systems is the more sustainable requires a differentiated case-by-case approach that considers various factors along the entire value chain. We therefore advise our customers to comprehensively and individually evaluate the appropriate product solutions for their specific needs.

Our product recommendations

Our product recommendations

Here you can also find out how you can use our effect coatings to impressively set the scene for your chocolate packaging.

DISCOVER