ECOLEAF® - Use Case for Personal Care

More than ever, sustainability is a must for brands as consumers actively seek products that align with their ecological values. Changes in legislation are making the disclosure of such information more visible to the consumers too, resulting in a change in consumption habits.

For personal care products, a need to differentiate and stand-out on the shelf is one of the reasons why metallization is found so prominently across this segment.

ECOLEAF® enables you to benefit from both of these aspects, maintaining your high-quality metallic finishing BUT more sustainably when compared to other technologies – we call it On-demand Metallization!

Validated examples

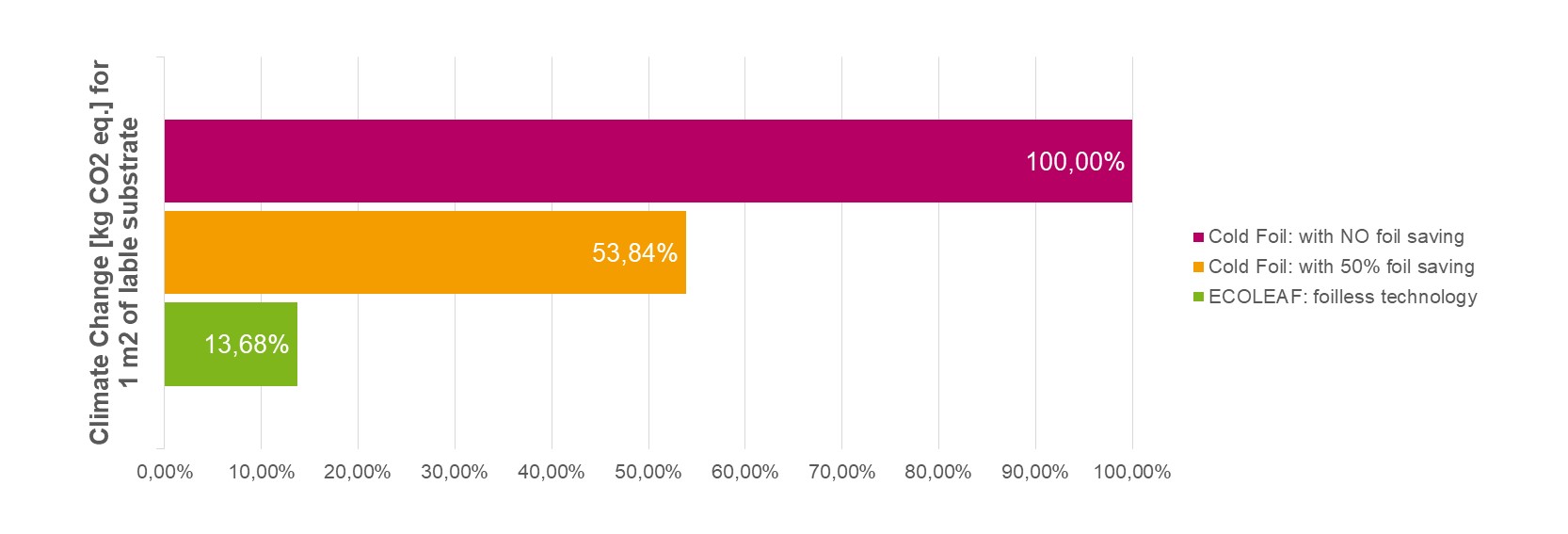

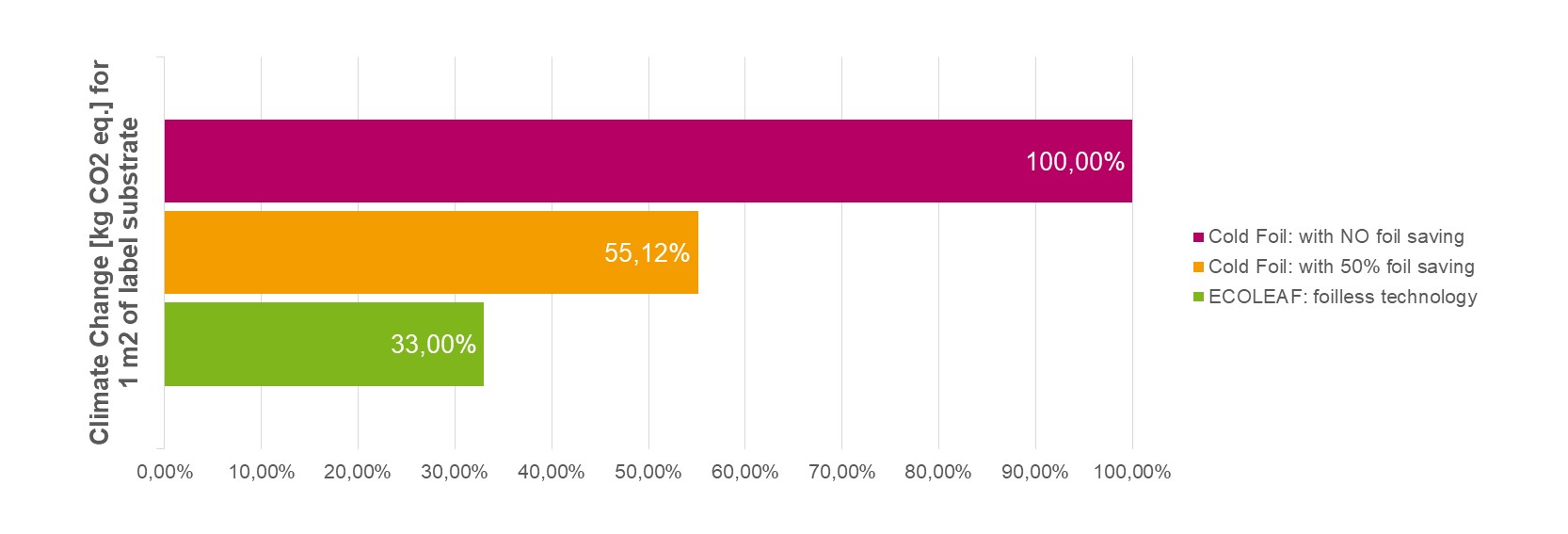

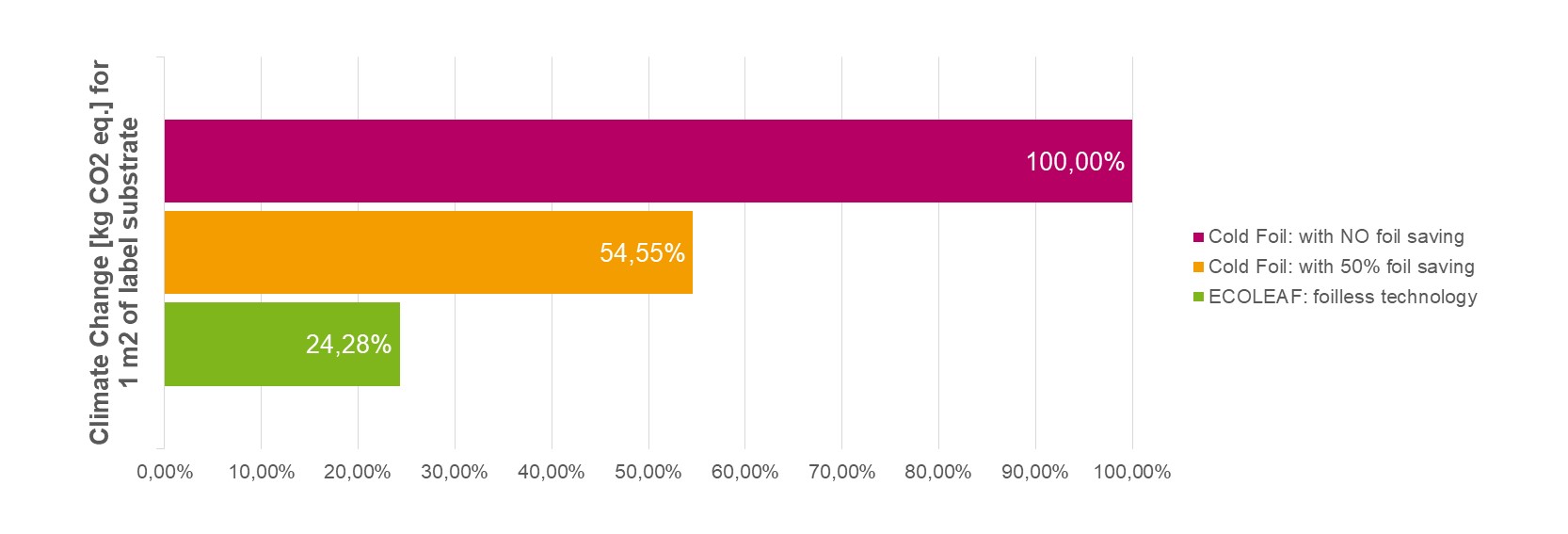

The below examples illustrate the CO2eq saving ECOLEAF® delivers when compared to a traditional cold foil transfer method.

Foil saving is the method to reuse as much foil as possible in production – calculated in % foil saving.

CO2 indicator for ECOLEAF® metallization produced in flexo in comparison to cold foil.

- No foil saving: No optimization in production (100% value).

- 50% foil saving: An optimization process in production to reduce foil wastage.

Ladouce Shower gel case

- Similar products found in natural cosmetics

- 8,5% metallization across the surface of the label

- Overprinted with CMYK

Bloom Shampoo case

- Similar products found in personal care markets

- 5,7% metallization across the surface of the label

- Overprinted with CMYK

- Simulated gold

MASC. Shampoo case

- Similar products found in personal care markets

- 5,7% metallization across the surface of the label

- Overprinted with CMYK

- Simulated gold

Corell Shampoo case

- Similar products found in premium or masstige personal care markets

- 24% metallization across the surface of the label

- Overprinted with CMYK

Joba Soap case

- Similar products found in hand care and home care markets

- 19,3% metallization across the surface of the label

- Overprinted with CMYK

Do you have any questions? Contact us and we will be happy to advise you on your individual requirements.

Using the same data sets captured in the LCA database we can effectively recalculate the CO2eq of any other label.

By measuring the metallized ink coverage, the width of metallization and the surface area of the label and putting these into our database we can calculate the savings in CO2eq ECOLEAF® offers compared to traditional metallization methods – giving you a solid indication of your overall potential CO2 savings.

At ACTEGA we take a holistic approach to sustainability by considering all aspects that are important for a sustainable solution.

For this reason, we carried out full Life Cycle Assessments (LCA) of the ECOLEAF® technology in 2020 and 2023. These LCAs were reviewed and verified by three independent external experts from the industry in accordance with the requirements of the international standards for LCA ISO 14040 and 14044 Life Cycle Analysis.

The original LCA was prepared by Sphera Solutions, Inc. ("Sphera") in 2020 with reasonable skill and care and is not accountable to ACTEGA or any third party for any matters beyond the scope agreed for the project. The LCA was reviewed by ALTANA's internal experts in 2023 and revised with current data and results.

The LCA model was created using the GaBi 10.6.1 software system for life cycle engineering. The 2022 LCA database provides the life cycle inventory data for several of the raw and process materials obtained for the background system.

In 2023, the data was revalidated by a panel of three external experts.

Take the next step towards your commitment to sustainability and capturing consumer attention! Order now your ECOLEAF® printed samples and convince yourself.